COMPREHENSIVE SEPTIC ROOM SERVICE

Steps to install the CREAMEDIC Solutions for infection control in septic rooms.

Evaluation of the facilities for the implementation of Solutions for infection control in septic rooms.

Preventive and corrective maintenance of Solutions for infection control in septic rooms.

Fitting of the maceration area.

Installation of hospital-level equipment and furniture for the septic room.

Efficient supply for a rationed storage of consumables.

Coordinated control and supervision with the users of Solutions for infection control in septic rooms.

Evaluation of the facilities for the implementation of Solutions for infection control in septic rooms.

Installation of hospital-level equipment and furniture for the septic room.

Elements that comprehend the Solutions for the control of infections in septic rooms

Pasos para la instalación de Soluciones para el control de Infecciones en cuartos sépticos

The success in the operation of the maceration system is proportional to the training level of the system users.

Each Hospital Unit or Care Center is analyzed in a specific way, taking into account the variables of the place where the system is installed, as well as the operation of the facilities.

TECHNICAL SPECIFICATIONS FOR THE INSTALLATION

Considerations for the installation of the clinical maceration systems.

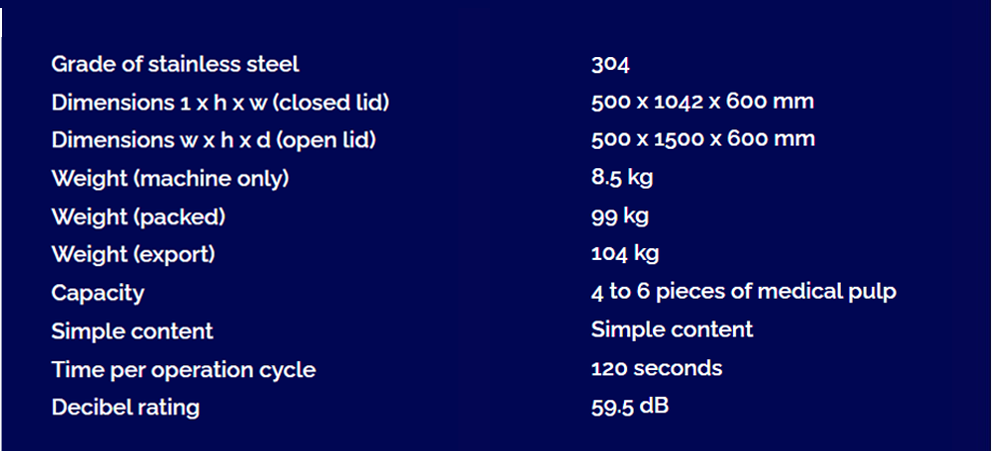

General

Grade of stainless steel | 304 |

Dimensions 1 x h x w (closed lid) | 500 x 1042 x 600 mm |

Dimensions w x h x d (open lid) | 500 x 1500 x 600 mm |

Weight (machine only) | 8.5 kg |

Weight (packed) | 99 kg |

Weight (export) | 104 kg |

Capacity | 4 to 6 pieces of medical pulp |

Simple content | Simple content |

Time per operation cycle | 120 seconds |

Decibel rating | 59.5 dB |

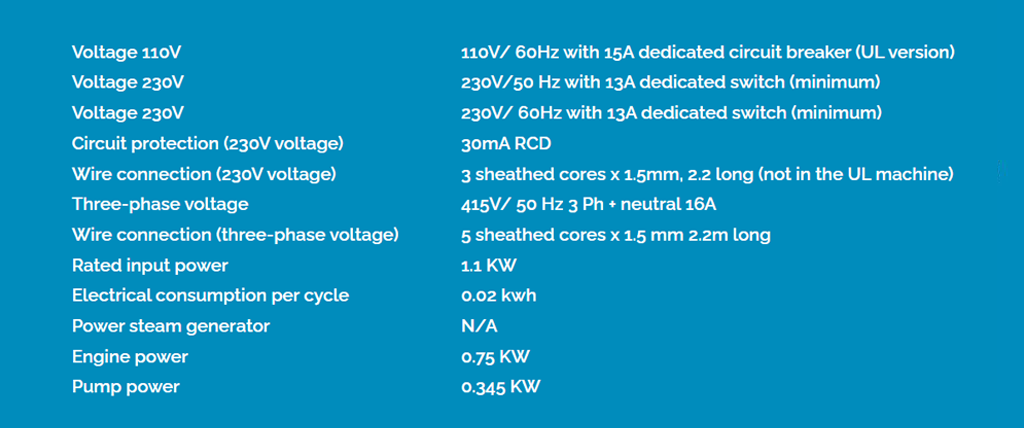

Electric

Voltage 110V | 110V/ 60Hz with 15A dedicated circuit breaker (UL version) |

Voltage 230V | 230V/50 Hz with 13A dedicated switch (minimum) |

Voltage 230V | 230V/ 60Hz with 13A dedicated switch (minimum) |

Circuit protection (230V voltage) | 30mA RCD |

Wire connection (230V voltage) | 3 sheathed cores x 1.5mm, 2.2 long (not in the UL machine) |

Three-phase voltage | 415V/ 50 Hz 3 Ph + neutral 16A |

Wire connection (three-phase voltage) | 5 sheathed cores x 1.5 mm 2.2m long |

Rated input power | 1.1 KW |

Electrical consumption per cycle | 0.02 kwh |

Power steam generator | N/A |

Engine power | 0.75 KW |

Pump power | 0.345 KW |